“I can take one of these cams and it will trigger a memory.”

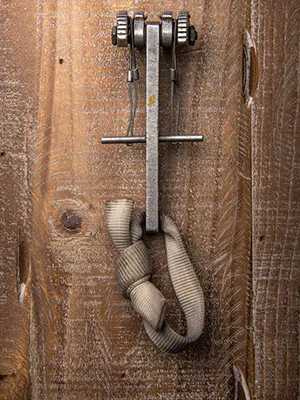

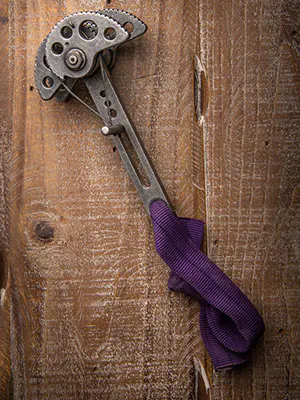

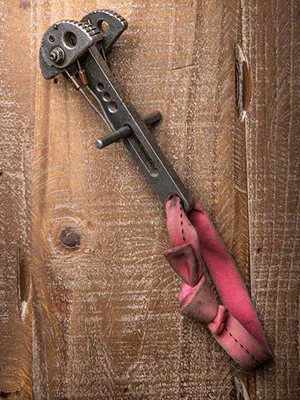

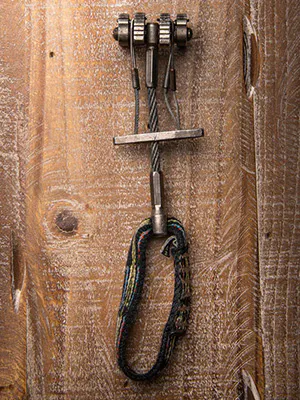

Paul Piana holds a worn, rigid stem Friend with a tattered, hand-sewn blue sling in his weathered hands.

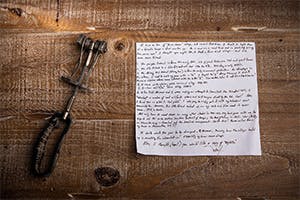

The 65-year-old Wyoming climber then pulls out a piece of paper, an ink pen and begins to write.

These cams were used on the FFA of the Salathé ...

Then his mind drifts.

Words by: Chris Parker

Photos: Bill Hatcher, Andy Earl, and Christian Adam

THE SALATHÉ

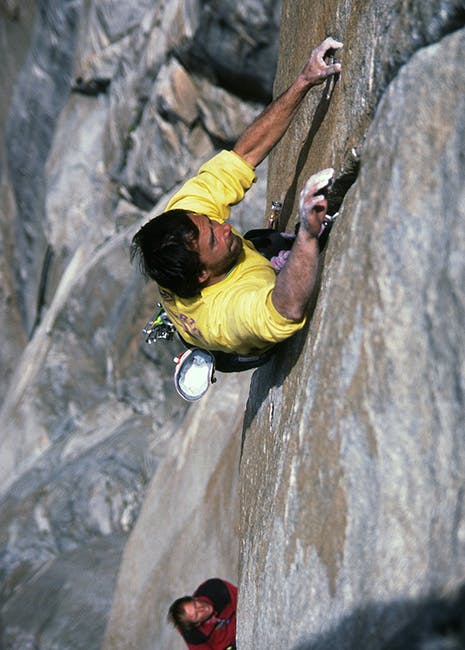

The year is 1988. Paul, clad in a bright yellow sweatshirt and sporting a week’s worth of stubble, eyes the “home-free” knob just out of reach while perched on El Capitan’s daunting Salathé headwall.

With 3,000 feet of air beneath his feet, Paul clings to a few crimps and granite smears and studies the next sequence. He knows he has to trust his friends—one being the strong Wyoming cowboy named Todd Skinner holding the other end of the rope. The second being his gear, including a rigid-stem Friend with a blue 9/16’s sling he sewed himself.

Putting his faith in his homemade bar tacks, his abilities, and his belayer … he jumps.

The fall came with a gust of rushing air. Paul’s body spun upside down as he hurtled backwards into space. The pine trees thousands of feet beneath him on the Valley floor quickly came into focus and grew larger before the rope came taught, leaving him dangling with dizzying exposure.

The 32nd pitch of the Salathé, for now, remained un-freed.

But at least the gear held.

“I never had the facility to try and break these things,” says Paul as he reminisces about his gear. “I guess my weight and Todd’s and other friends that happened to fall on them was test enough.”

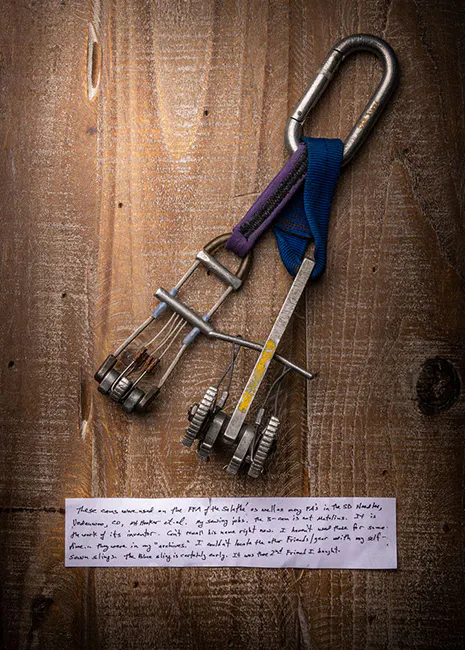

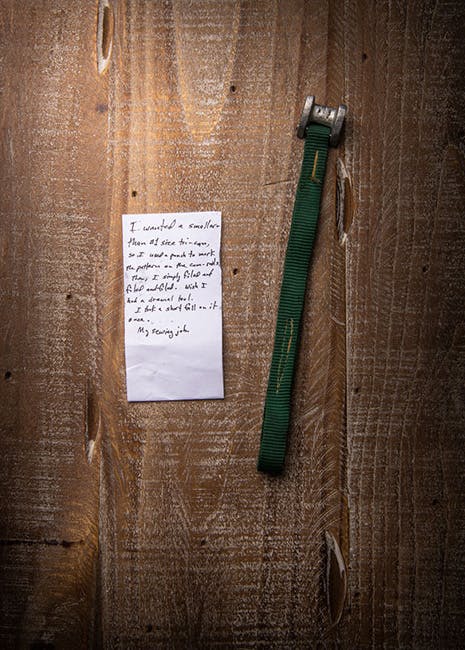

Still curious, however, Paul recently surprised the Black Diamond quality engineers with a box of his archival cams and hand-sewn slings. Each piece came with a meticulously handwritten note, describing the adventures these pieces had accompanied him on.

Paul started climbing in 1966—roughly a decade before the first cams ever hit the market—so these relics of his rack have seen nearly 40 years of action. For perspective that’s more days on rock than many of the BD engineers fondling these worn widgets have been alive.

A second-generation native of Newcastle, Wyoming, Paul grew up with the dream of becoming a World War II fighter pilot like his uncle.

“That was out of my reach,” he laughs. “So, I decided that rock climbing would be the right deal. For a long time, I didn’t know what the hell I was doing. But it was sure fun.”

Fortunately, the Black Hills, Needles, of South Dakota are only 35 miles from Paul’s pastoral hometown. A climbing area now renowned for its psychological testpieces, success in the Needles is more about running it out and dialing in tricky gear placements rather than the physicality of the moves.

So, Paul learned early on to trust his gear. Plus, he had the flaring cracks of Vedauwoo, Wyoming, just down the road to practice his rock-craft. Eventually, he began adding his own first ascents to the nearby western climbing areas, until his infatuation with the military pulled him away from the sport.

THE ULTIMATE PARTNERSHIP

“I dreamed of that route for 4 years,” says Paul, thinking about his first few days fresh out of the marine corp.

It was 1979, and Paul was back in Vedauwoo, working on the first ascent of what would become Spider God (5.11b R).

That’s when the strange kid he’d recently met at the University of Wyoming’s cafeteria came strolling up.

“I had gone back to school at the University of Laramie, and I would walk over to the cafeteria, which had these sandstone blocks, and long story short, it made a great traverse,” says Paul. “Anyway, I went over one day to do some traversing, and this young kid showed up.”

What struck Paul right away was the gear the kid was wearing.

“He had on a pair of size 45 Royal Robbins boots, and he had the 1950’s gear that his dad had, you know, clanking around with pitons to come bouldering on a 20-foot high wall,” he laughs. “He had these five buddies with him, you know, going out to conquer the mountain!”

So, when that same kid came sauntering up to Paul’s project in Vedauwoo a few days later, Paul was happy to let him have a go.

“He just flailed,” says Paul. “He had on those giant, way too big Royal Robbins boots, but … he got to the top, which was kind of remarkable!”

After that, the kid, named Todd Skinner, became Paul’s willing partner.

“The problem was, he got better really fast,” says Paul.

It also helped that Todd scored a pair of “climbing snug” EB’s.

Eventually, says Paul, Todd “was occasionally stealing my routes. And then pretty soon I would occasionally steal his, so it worked out pretty well!”

The two Wyoming boys struck up a partnership that would last for over two decades. Todd, the young blond cavalier cowboy who pioneered training tactics that would raise standards from Hueco Tanks to Yosemite, and Paul, the dark-haired stalwart with grace and power to match. Together they would forever shift the paradigm of what was possible in the world of climbing.

THE GEAR THAT CHANGED THE GAME

“When we first got cams, they said it wasn’t fair to use them,” says Paul.

He remembers the first time he ever saw a cam.

“I was up at Devil’s Tower one day, oh, about 1978, and Ron Kauk and some Yosemite guys were up there rigging a route for the TV show Wild World of Sports. Ron clandestinely pulled out these really weird looking things. Those were the first Friends I ever saw.”

The Friends were made by their inventor, Ray Jardine. A former aerospace engineer, Jardine would usher in the world’s first 5.13 in 1977 with a first ascent of The Phoenix in Yosemite. Free climbing the parallel sided splitter was made possible by utilizing the spring-loaded camming devices he’d been tinkering with. By ’78, though Friends were still relatively unknown outside of the Valley, the Californian free climbers like Kauk were already putting them to the test.

“I thought I’d never see them again,” says Paul. But of course, Friends eventually became ubiquitous in the free climbing game. To climb parallel sided cracks, you had to have them.

Paul was one of the early adopters of the cams, despite the media at the time declaring them a form of “cheating.”

“I loved them because I was at Vedauwoo, with flaring cracks, and nothing else would work,” he says.

Over time, Paul collected more cams, many of them becoming crucial pieces of his rack for the next 40 years, including the second Friend he ever bought, which he outfitted with a hand-sewn, blue 9/16’s sling.

When asked why he sewed his own slings, Paul is candid.

“I was always a tightwad, and it was cheaper,” he laughs. “And it was kind of fun.”

Paul learned to sew as a literature student at the University of Laramie.

“I had to have another elective, so I took a sewing class,” he says. “I made a lot of weird stuff, and they just didn’t understand what I was making. I didn’t care how beautiful it was, it just had to be strong. And that’s how I came up with my bar tacks.”

Paul acquired an old Pfaff sewing machine that he describes as “heavy duty,” and began modifying and creating his own gear, from packs to what he now calls his “Paul-sewn” slings that still hang from his rack.

He improvised his own way of creating “fake bar tacks” on the slings, but he never doubted their strength.

“What I’d do is I’d make a single line of stitching, and then I’d go over it again with a zig zag, just a little bit, and then I’d make a wider one and a wider one and a wider one.”

He adds:

“I think they were all bombproof. The stitching was probably stronger than the webbing.”

Paul recently pulled a few pieces off his rack to share with Black Diamond so he could once and for all settle his curiosity.

“Nowadays, it’ll be really interesting to see how strong those slings are,” he says. “I never had anything tested other than falling on them. Never failed.”

However, he made sure to specify that the cams remain undamaged.

“I still use them,” he says. He also explained that there’s a deeper connection to these pieces. “It’s just a tool, but it has taken you to a lot of places.”

He adds:

“They’re friends, and I don’t mean trademark friends. I mean they're my buddies. I can hold these cams and think about good times or bad times …”

With those last few words hanging in the air, he trails off. The gear, once again, has become a vehicle, and for a split-second Paul is back on the crux pitch of the Salathé headwall. His now deceased partner is with him once again, holding the rope. He can hear Todd’s encouragement as he eyes the “home free” knob.

With friends he knows he can trust beneath him, Paul jumps … and latches the finishing hold. At 5.13b, a couple of Wyoming cowboys have proven to the world that El Cap goes free.

For Paul, these cams still hold that memory.

QC LAB: THE STRENGTH OF PAUL’S HAND-SEWN SLINGS

I received an email out of the blue from Paul Piana.

KP, would you be interested in testing some of my home sewn, and knotted 40-year-old slings as well as some of the slings on my cams? You might shudder at some of the gear I still use … They were used on first ascents at Vedauwoo, the Black Hills, Devils Tower, Eldo, the Great Canadian Knife, Mt. Poi in Kenya, in Greenland and the FFA of the Salathe Wall.

Uh, yeah. RAD!

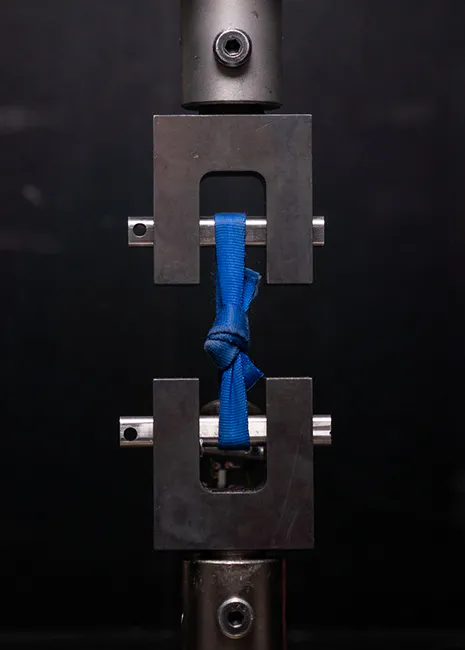

Hunter, one of the crack crew of QA Engineering wizards (yes ladies... he's single) fired up the tensile tester and we got to breaking some of the most historic gear you could imagine. Just holding some of this stuff and reading Paul’s hand-written notes about the history of some of these pieces was incredible. I just kept reminding Hunter – DON’T BREAK ANY OF THE CAMS … just the slings!

As a quick refresher:

• For a sling to be CE certified it must meet 22kN (4946lbf)

• Cams are tested as a complete unit, but to put it in perspective, the sling only of a BD cam must meet an internal rating of 20kN (4496lbf). This ensures the sling is up to snuff when assembled onto a cam, whose ratings are all less than 20kN.

THE TESTING

In order to get a close comparison, we tested similar configurations to Paul’s gear, but with new webbing. I.E. water knot in 9/16” Supertape, and water knot in 1” tubular webbing.

The slings were tested in standard testing configuration using 12mm pins.

Results

|

Material |

Configuration |

Sample |

Peak Load (lbf) |

Peak Load (kN) |

Failure Type |

|

9/16" Supertape |

Water Knot |

NEW Webbing |

2561 |

11.4 |

web @ knot |

|

Water Knot |

Small blue TCU |

2908 |

12.94 |

web @ pin |

|

|

Water Knot |

Pink TCU |

2094 |

9.31 |

web @ pin |

|

|

Water Knot |

Pink Medium Friend |

2714 |

12.07 |

web @ pin |

|

|

Water Knot |

Blue Sling |

2301 |

10.24 |

web @ pin |

|

|

Factory Sewn Sling |

NEW Sling |

>5000 |

>22 |

web @ tack |

|

|

Factory Sewn |

Flexible Friend |

2979 |

13.25 |

web @ tack |

|

|

Factory Sewn |

Pink Webbing |

3017 |

13.42 |

web @ pin |

|

|

Home Tacked |

Purple TCU |

3040 |

13.52 |

web @ tack |

|

|

1" Tubular |

Water Knot |

NEW Webbing |

3787 |

16.8 |

web @ knot |

|

Water Knot |

Small Friend with white sling |

2785 |

12.39 |

web @ pin |

|

|

Water Knot |

Large purple friend |

3270 |

14.55 |

web @ knot |

|

|

Home Tacked |

Large blue friend |

4158 |

18.5 |

web @ tack |

|

|

9/16" Tape |

Home Tacked |

Tri-cam |

1578 |

7.02 |

web @ pin |

OBSERVATIONS

As always, it's hard to compare off of one data point, and especially hard to call these comparisons apples-to-apples because there undoubtedly has been different variations and strengths of super tape and 1” webbing from various suppliers over the last 40 years. Regardless, here it goes:

GENERAL

- When we destructively test gear, we're not only interested in the load, but also the failure mode. Typically, webbing fails at the knot or the tack. When it fails at the pin, that means that the webbing itself has become the weak point—either by means of frictional wear or general degradation. This result can be seen in several of the tests of Paul’s gear.

- Some of Paul's gear had different levels of sun bleaching which undoubtedly contributed to the end results.

9/16” SUPERTAPE

- Paul's old water-knotted supertape used as slings or the slings on his cams was right in-line, and sometimes even stronger than a brand-new comparable piece of Supertape with a water knot.

undefined - Paul's old factory sewn slings tested well below what a brand-new sling is required to meet (ie. 22kN). This isn’t surprising as we've seen in previous QC lab tests.

- Paul's home-tacked sling on his purple TCU performed incredibly close to the other factory sewn 9/16” supertape slings.

1” TUBULAR WEBBING

- Once again, Paul's old water-knotted 1” tubular webbing slings he had on some cams tested less than, but not too far off a brand-new equivalent.

undefined - Paul's home-tacked 1” sling actually performed better than the knotted equivalents and even better than a brand-new knotted sling.

9/16” TAPE

- Now this is different than Supertape, it's not tubular and isn't expected to be as strong. We didn’t have any laying around so couldn't do a direct comparison. But when comparing to the strength of an equivalent-size new Tri-cam, this value seems to be in-line and the fact that it broke at the pin shows that the home sew job wasn’t the weak point.

CONCLUSIONS

Paul's old gear and home-sewn slings did about as well as could be expected and in all cases wouldn't have had a problem holding a typical fall.

Knotted slings when comparing old to new fared better than when comparing an old sewn sling and a new sewn sling.

Anytime you knot a sling you're going to reduce the overall strength. A good general rule of thumb is that knots can reduce a sling’s strength by up to 60%. There is some info in the QC lab archives here:

LEARN MORE IN OUR QC LAB ARCHIVES

Prolonged exposure to sun and/or abrasion can reduce the strength of slings. Some previous info here can be found in various articles in the archives:

QC LAB GEAR DOESN'T LAST FOREVER

THE BOTTOM LINE

At the end of the day, Paul's old gear held up pretty well, and his home sew jobs weren’t bad. However, I definitely can’t recommend sewing your own slings, using knotted slings nowadays or using 40-year-old gear.

Textiles weaken with time as is evident in Pauls’ sewn slings, losing approximately 40% of their strength when compared to new.

At BD from our sling instructions:

Instructions for Dogbones and Runners

Climbing gear does not last forever. Inspect your gear before and after each use and retire it when it fails inspection or when it reaches its maximum lifespan, 10 years after the date of manufacture for plastic or textile products/components, even if unused and properly stored. The lifespan of metal gear is not limited by age.

Process control, quality testing, etc. is a real thing and most reputable manufacturers have many steps in place to ensure your gear meets the required standards. As well, gear progresses – gear has become significantly lighter, more streamlined, and more tech over the last 40 years. And take it from me, I need all the help I can get.

Be Safe out there,

KP

Featured Gear