SO FINDEST DU DIE RICHTIGEN BACKCOUNTRY-SKI

Wähle die besten Bretter für dein Lieblingsgelände aus.

Du hast schon ein Konto?

Melde dich an, um schneller auszuchecken.

Add 100 EUR more to quality for free Shipping!

€0,00 EUR

If you have been leading ice long enough you’ve most likely had a screw hit rock before the hanger was flush with the ice. Not only are you bummed because you likely just damaged the razor-sharp teeth of your screw; you now have some options to weigh. What if you don’t have a shorter screw? What if there’s no thicker ice nearby? You have some options – down climb to thicker ice, continue climbing up to thicker ice, or, as a last resort place the screw you have and tie it off or clip the hanger. Before we get into which option is best, we first need to understand how ice screw placements fail.

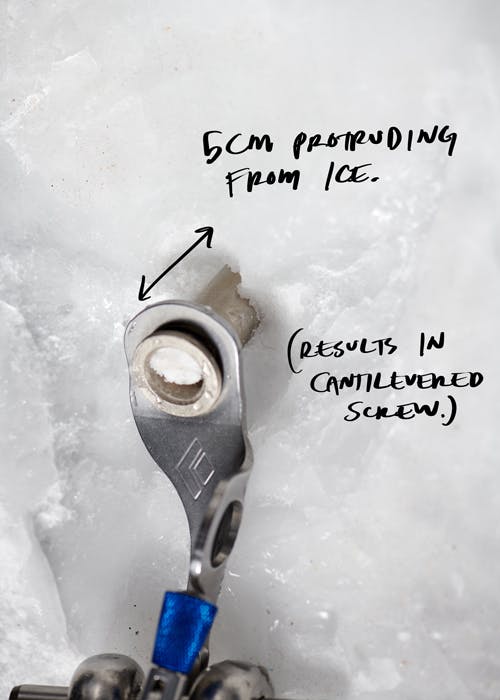

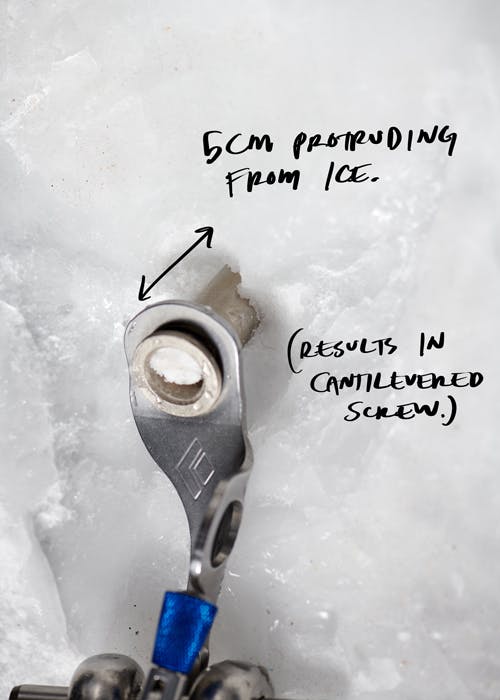

Ice screws themselves are very strong, but they rely on the support of the surrounding ice which can be highly variable. In a textbook placement, with the hanger flush to the ice, an applied load will stress the ice surrounding the screw and eventually cause the ice to fail and fracture in the shape of a cone around the last 3-5 centimeters of the screw nearest to the hanger. Once this occurs, the exposed section of the screw body becomes cantilevered and no longer supported by ice. The now cantilevered screw body, unable to support the load alone, will begin to bend until the hanger is levered off the head, the screw body fails, or the screw pulls out of the ice.

Wenn die Eisschraube nicht bündig am Hanger befestigt ist, jetzt für immer bekannt alsSchraubtrusion, die Festigkeit der Verankerung wird bereits vor Anlegen einer Last durch den auskragenden Schraubenkörper beeinträchtigt. Durch den erhöhten Hebel wird jede am Hänger angelegte Last einen Multiplikatoreffekt auf die im Eis entstehenden Spannungen haben, was zu einem Versagen bei geringeren Lasten führt. Daher ist es wichtig, eine Schraube immer bündig mit dem Hänger zu versenken. Falls das jedoch nicht möglich ist, bleiben einige Fragen: Reduziert das Festbinden einer Schraube den Hebel tatsächlich so weit, dass dies eine bessere Option als das Abschneiden des Hängers darstellt? Gibt es einen Unterschied zwischen der Verwendung einer Aluminium- oder Stahlschraube für Eis?

To answer this question, we headed into the QA lab to do a few quick tests and evaluate the tied-off vs clipped strength for both the BD Express (steel) and the BD Ultralight (aluminum) ice screws when placed in ice with screwtrusion. This data must be taken with a grain of salt because we’re talking about a very limited data set which is not statistically significant. It is also important to keep in mind that this testing was conducted in laboratory ice, which is solid, homogenous, and doesn’t have the same inconsistencies that are often found in the wild.

First, let’s examine the strength of both aluminum and steel screws when placed flushed to the ice, and then when placed with 5cm of screwtrusion. Three samples of both the 16cm aluminum and 16cm steel screws were tested in each configuration. For the sake of consistency, all test samples were placed perpendicular to the ice surface (at 0 degrees) per the EN568 standard test method.

Unter Bezugnahme auf die passiven und aktiven Richtlinien zum Felsenschutz beträgt die minimale Haltekraft, die sicher als laufende Sicherung verwendet werden kann, 7kN (siehe Anhang A der EN12276). Die Stahl BD Express Schrauben führen zu Spitzenbelastungen, die durchgängig über der 7kN-Marke liegen, bei 5cm von Schraubenextrusion. Unter Berücksichtigung der oben genannten Running Belay-Richtlinien ist es für dich wahrscheinlich in Ordnung, wenn Stahlschrauben leicht herausragen. Allerdings gilt das nicht für die ultraleichten Eisschrauben aus Aluminium. Weitere Tests und Regressionsanalysen zeigen, dass die Aluminium Ultralight Eisschrauben diese Haltekraft nur dann bieten, wenn sie 3.5cm oder weniger aus der Eisoberfläche herausragen.

Es ist erwähnenswert, dass es zwar möglich ist, im Feld Lasten von über 7kN zu erreichen, aber das ist nicht üblich. Selbstverständlich gilt das altgediente Mantra beim Eisklettern – der Leader darf nicht fallen. Mit vielen scharfen Sachen an deinem Körper zu fallen, ist quasi ein Rezept für Verletzungen…

Using the passive and active rock protection guidelines as reference, the minimum holding force to be safely used as a running belay is 7kN (refer to Annex A of EN12276). The steel BD Express screws result in peak loads consistently above the 7kN mark with 5cm of screwtrusion. Given the above running belay guidelines, you’re probably ok with steel screws protruding slightly. However, this is not the case for the aluminum ultralight ice screws. Further testing and regression analysis reveals that the aluminum Ultralight ice screws will provide this holding force only when protruding 3.5cm or less from the surface of the ice.

It is worth noting that although achieving loads in the field upwards of 7kN is possible, it is not common. It should go without saying that the old school mantra for ice climbing still stands – the leader shalt not fall. Falling with lots of sharp things attached to your body is a recipe for injury…

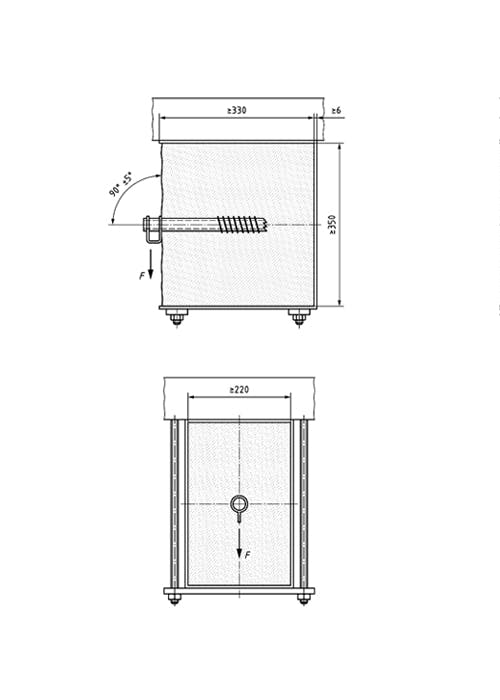

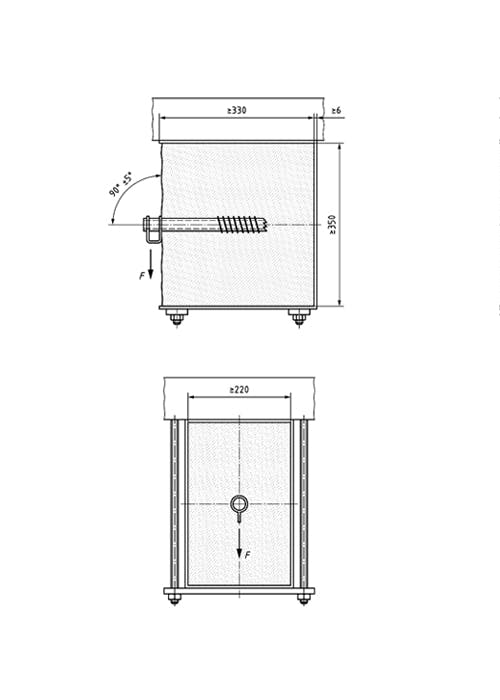

Das Ziel eines Schraubensicherungsverfahrens ist es, den Hebel auf den Schraubenkörper zu verringern und die Spannungen im Eis, das die Befestigungsstelle umgibt, zu reduzieren. Die oben gezeigten Daten, erneut getestet mit Schrauben, die senkrecht zum Eis stehen, zeigen, dass sowohl die abgesicherten Stahl- als auch die Aluminiumschrauben Werte liefern, die über dem zuvor erwähnten Mindestwert von 7kN für eine laufende Sicherung liegen – wenn im Laboreis getestet. Ein großes Problem besteht darin, dass es schwierig ist, zu verhindern, dass die Schlinge während eines Absturzes in Richtung des Hängers verrutscht. Wenn die Schlinge in Richtung des Hängers rutscht, erhöht sich der Hebel auf den nicht gestützten Schraubenkörper, was potenziell zu einem Stoßbelastung führen und sogar durch die Gewinde oder den Hänger zerschnitten werden kann.

Wie wir alle wissen, ist es Best Practice, Schrauben in einem positiven Winkel (mit den Zähnen nach oben) anzubringen. Allerdings ist das Festbinden einer Schraube ein Sonderfall, der erfordert, dass die Schraube senkrecht zum Eis oder in einem negativen Winkel (mit den Zähnen nach unten) platziert wird. Wird die Schraube im negativen Bereich zwischen 0 und 15 Grad angebracht, bleibt die Schlinge fest am Eis haften und erzielt die höchste Haltekraft. Die meisten Stürze erzeugen zudem eine nach außen gerichtete Kraft auf die Schlinge, die diese selbst bei einem perfekten Festbinden in Richtung des Hängers ziehen kann.

Unter idealen Laborbedingungen sind Befestigungen sicherlich stärker als angesetzte Haken, wenn sie 5cm aus dem Eis ragen. Allerdings sollte man diese Methode aufgrund der vielen Faktoren, die die Festigkeit beeinflussen, möglichst vermeiden. Wenn du keine kürzere Schraube hast und gezwungen bist, eine Befestigung vorzunehmen, dann achte darauf, dass die Schraube senkrecht oder in einem negativen Winkel eingesetzt wird – auch wenn das bedeutet, dass du sie herausziehen und neu im Eis verankern musst. Es ist entscheidend, dass mindestens 10cm der Gewinde in hochwertigem Eis sitzen. Entferne verdächtiges Oberflächeneis und benutze für zusätzliche Stabilität eine Stahlschraube. Zum Schluss geh sehr vorsichtig vor, damit die Schlinge straff am Eis anliegt. Eine kürzere Schraube, die bis zum Anschlag im Eis verankert ist, ist immer stärker als eine lange Schraube, die lediglich befestigt wurde.

Es gab im Laufe der Jahre viel Diskussion über die Einstellwinkel. Allgemein ist bekannt, dass die stabilsten Platzierungen zwischen 10 und 15 Grad in positiver Richtung (Zähne nach oben) liegen. Das Eis um die Schraube herum ist das schwache Glied im System, weshalb es das Ziel ist, die Schraube so zu platzieren, dass die Belastung auf das Eis reduziert wird. Eine Schraube, die nach oben ausgerichtet ist, verringert die Druckspannungen im umgebenden Eis und richtet die Gewinde am Schraubenkörper besser an der Fallrichtung aus – beides erhöht die Haltekraft. Wenn sich die Schraube zu negativen Einstellwinkeln (Zähne nach unten) hin bewegt, nimmt die Haltekraft der Gewinde ab und die Belastung im Eis steigt aufgrund der Hebelwirkung der Schraube.

NOTE: The following only applies to 16cm or longer screws which are placed in at least 10cm of good quality ice. Screws less than 16cm in length do not have enough thread engagement to support the screw once the ice cones out.

Be safe out there.

Berry

Wähle die besten Bretter für dein Lieblingsgelände aus.

Von der Kletterwelt inspiriert, von Hand gefertigt – unsere Prints für Frühjahr 2026 erzählen ihre...

Von der Kletterwelt inspiriert, von Hand gefertigt – unsere Prints für Frühjahr 2026 erzählen ihre ganz eigene Geschichte.

Einfache Tipps zur Pflege und Reparatur deiner Steigfelle vom Reroute-Team.

Schau zu, wie Connor am Empath-Felsen in Kirkwood, Kalifornien, ein weiteres legendäres Testpiece abräumt.

Stell dir dein perfektes Outdoor-Outfit zusammen – egal ob strahlender Sonnenschein oder Schneesturm.

Black Diamond Athletin Angela Hawse ist eine Wegbereiterin für Veränderung.

Das brauchst du für jede Art von Skitouren-Abenteuer.

Stell dein Setup für die nächste Skitour perfekt ein.

Begleite BD-Athlet Yannick Glatthard tief in die Schweizer Alpen, während er seine Heimatberge mit guten...

Begleite BD-Athlet Yannick Glatthard tief in die Schweizer Alpen, während er seine Heimatberge mit guten Freunden teilt.

Begleite Dorian Densmore und Mya Akins durch eine weitere Wintersaison voller steiler Alaska-Spines, versteckter Backyard-Couloirs...

Begleite Dorian Densmore und Mya Akins durch eine weitere Wintersaison voller steiler Alaska-Spines, versteckter Backyard-Couloirs und tiefer Abenteuer in den Bergen.

Wir bringen Licht ins Dunkel, wenn’s um Stirnlampen geht.

Schau dir an, wie BD-Athlet Alex Honnold hoch über Tahoe beim harten Trad-Klettern alles gibt.